GRAVITY GOODS ROPEWAY

6.1 Types of Planning

Mostly three types of planning are involved in

gravity ropeway construction.

a) Time planning

b) Resource planning and

c) Technical planning

6.1.1 Time planning

Time planning simply means to manage the time

effectively to get more work done in less time. It

means utilising minimum time to accomplish the

goals. More time consumption means more cost.

Time planning involves preparation of project

activities schedule using bar chart. Preparation

of project implementation schedule in the initial

stage is always helpful. A typical Critical Path

Network (CPN) diagram will be very useful to

know what activities are in critical path and

allows for effective time planning of activities

ahead. Additionally, the chart can be used for

optimising resources (labour, equipment and

material) by distributing them in a balanced way.

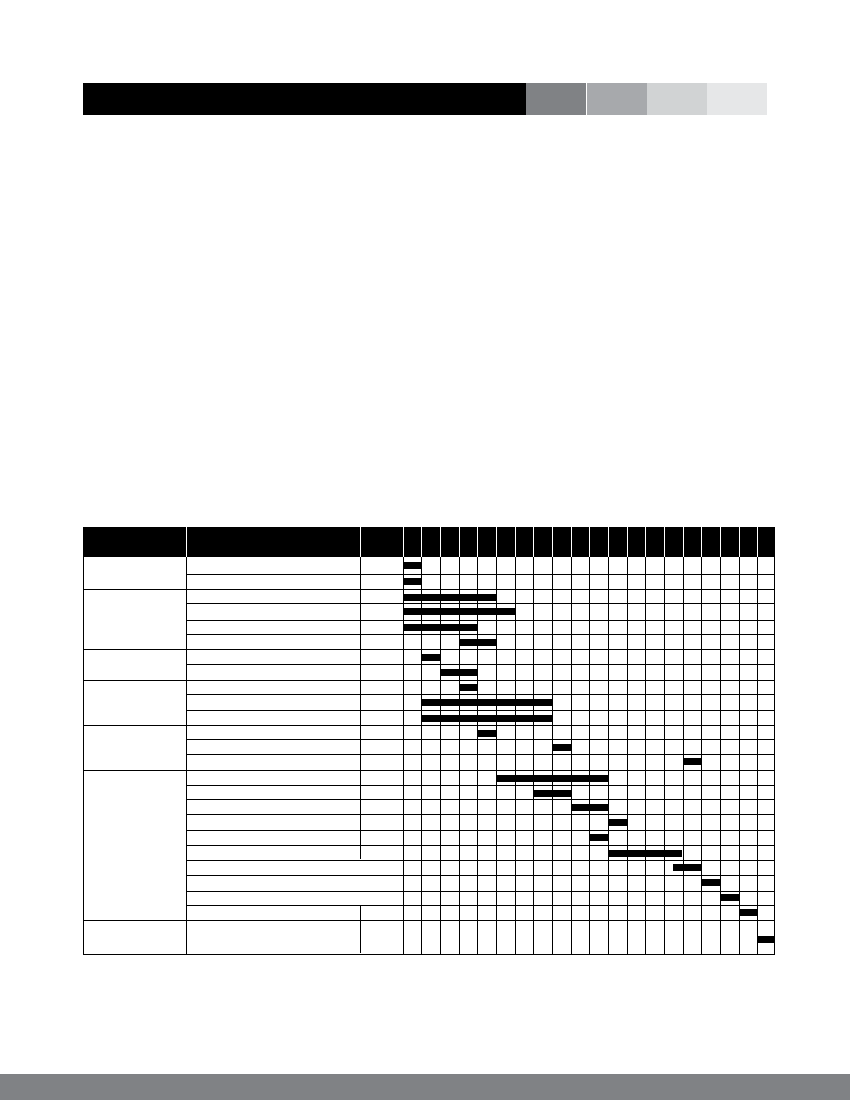

A typical time planning chart is shown in table 3.

Furthermore, this will also be a key tool for

monitoring progress by tracking the planned

versus actual milestones reached - both for

particular activities and for the overall project

implementation activities. If required such chart

may require revision as construction progresses.

Table 3: A typical time planning chart

scheduling

Time Planing

Items

Details

Time/

weeks 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

A) Agreement MOU Signing

Project Management training

B) Local materials Sand

collection and Gravel

preparation

Stones

Wood

C) Excavation

Site clearance and layout

Excavation

D)Procurement Cement and reinforcement rod

Fabrication and supply of steel parts

Wire ropes

E) Transportation Cement and reinforcement rod

Structural steel

Wire ropes

F) Execution

Masonray work

Plumb concrete

RCC work

Roofing

Sheave anchoragefixing

Curing and finishing works

Alignment clearance for cable laying

Cable laying and hoisting

Shave fixing and trolley installation

Test operation

G) Testing and Operation and maintenance

Commissioning training and commissioning

Source: Access for Opportunities Project, Practical Action Nepal Office

30